SCHEDULE ANALYSIS PROTOCOL

Forensic scheduling analysis basics

Forensic scheduling analysis, like many other technical fields, is both science and art. As such, it relies on professional judgment and expert opinion and usually requires many subjective decisions.

The most important of these decisions is what technical approach should be used to measure or quantify delay and to identify affected activities to focus on causation, and how the analyst should apply the chosen method.

The desired objective of this Recommended Practice is to reduce the degree of subjectivity involved in the current state of the art. This is with the full awareness that there are certain types of subjectivity than cannot be minimized let alone be eliminated.

Professional judgment and expert opinion ultimately rests on subjectivity. But that subjectivity must be based on diligent factual research and analyses whose procedures can be objectified.

By describing uniform procedures that increase transparency of the analysis method and the analyst's thought process, the guidelines established herein will increase accountability and testability of an opinion and minimize the need to contend with "black-box" or "voodoo" analyses.

Basic Premises and Assumptions

- Forensic scheduling is a technical field that is associated with, but distinct from, project planning and scheduling. It is not just a subset of planning and scheduling;

- Protocols that may be sufficient for the purpose of project planning, scheduling and controls may not necessarily be adequate for forensic schedule analysis;

- It is assumed that this document will be used by practitioners to foster consistency of practice and in the spirit of logical and intellectual honesty;

- All methods are subject to manipulation. They all involve judgment calls by the analyst whether in preparation or in interpretation;

- No forensic schedule analysis method is exact. The level of accuracy of the answers produced by each method is a function of the quality of the data used by the method and the accuracy of the assumptions and the subjective judgments made by the forensic schedule analyst; and

- Schedules are project management tools that alone do not demonstrate root causation or responsibility for delays. Legal entitlement to delay damages should be distinct and apart from the forensic schedule analysis methodologies.

Scope and Focus

This practice covers the technical aspects of forensic schedule analysis methods. It will identify, define and describe the usage of various forensic schedule analysis methods in current use. It is not the intent of the practice to exclude or to endorse any method over others. However, it will offer caveats for usage and cite the best current practices and implementation for each method.

The focus of the document will be on the technical aspects of forensic scheduling as opposed to the legal aspects. This practice is not intended to be a primary resource for legal theories governing claims related to scheduling, delays and disruption. However, relevant legal principles will be discussed to the extent that they would affect the choice of techniques and their relative advantages and disadvantages.

Accordingly, the practice will primarily focus on the use of forensic scheduling techniques and methods for factual analysis and quantification as opposed to assignment of delay responsibility. This, however, does not preclude the practitioner from performing the analysis based on certain assumptions regarding liability.

This practice is not intended to be a primer on forensic schedule analysis. The reader is assumed to have advanced, hands-on knowledge of all components of CPM analysis and a working experience in a contract claims environment involving delay issues.

Nor is this practice intended to be an exhaustive treatment of CPM scheduling techniques. While it explains how schedules generated by the planning and scheduling process become the source data for forensic schedule analysis, it is not intended to be a manual for basic scheduling.

This practice is not intended to override contract provisions regarding schedule analysis methods or other mutual agreement by the parties to a contract regarding same. However this is not an automatic, blanket endorsement of all methods of delay analysis by the mere virtue of their specification in a contract document. It is noted that contractually specified methods often are appropriate for use during the project in a prospective mode but may be inappropriate for retrospective use.

It is not the intent of this practice to intentionally contradict or compete with other similar protocols. All effort should be made by the user to resolve and reconcile apparent contradictions.

This practice deals with CPM-based schedule analysis methods. It is not its intent to exclude analyses of simple cases where explicit CPM modelling may not be necessary and mental calculation is adequate for analysis and presentation. The delineation between simple and complex is admittedly blurry and subjective. For this purpose, a ‘simple case' is defined as any CPM network model that can be subjected to mental calculation whose reliability cannot be reasonably questioned and allows for effective presentation to lay persons using simple reasoning and intuitive common sense.

Finally, the practice is an advisory document to be used in conjunction with professional judgment based on adequate working experience and knowledge of the subject matter. It is not intended to be a prescriptive document that can be applied without exception.

The recommended protocols will aid the practitioner in creating a competent work product, some cases require additional steps and some require less. Thus, a departure from the recommended protocols should not be automatically treated as an error or a deficiency as long as such departure is based on a conscious and sound application of schedule analysis principles.

Taxonomy and Nomenclature

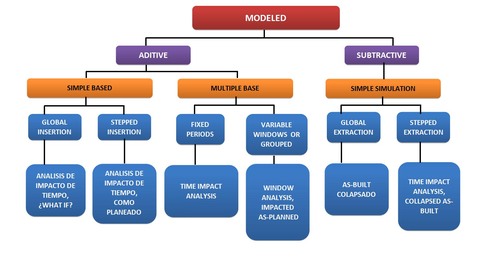

The practice's taxonomy is a hierarchical classification system of known methods of schedule impact analysis techniques and methods used to analyze how delays and disruptions affect entire CPM networks. For example, you will find methods like the window analysis or collapsed as-built classified here. Procedures such as fragnet modelling, bar charting and linear graphing, are tools, and not methods. Therefore, they are not classified under this taxonomy.

The practice's taxonomy is a hierarchical classification system comprising the five layers:

- Timing;

- Basic methods;

- Specific methods;

- Implementation of basic methods; and

- Implementation of specific methods.

Layer 1: Timing

The first hierarchy layer distinguishes the timing of when the analysis is performed, consisting of two branches, prospective and retrospective.

1. Prospective analyses are performed in real-time, prior to the delay event, or where the

analysis takes place, in real-time, contemporaneous with the delay event. In all cases prospective analysis consists of the analyst's best estimate of future events. Prospective analysis occurs while the project is still underway and may not evolve into a forensic context.

2. Retrospective analyses are performed after the delay event has occurred and the impacts are known. The timing may be soon after the delay event but prior to the completion of the overall project, or after the completion of the entire project. Note that forward-looking analysis (such as ‘additive modelling') performed after project completion is still retrospective in terms of timing.

What is classified here is the real-time point-of-view of the analyst, and not the mode of analysis (forward-looking or hindsight). In other words even forward-looking analysis methods implemented retrospectively has the full benefit of hindsight at the option of the analyst.

This distinction in timing is one of the most significant factors in the choice of methods. For example, contract provisions prescribing methods of delay analysis typically contemplate the preparation of such analysis in the prospective context, in order to facilitate the evaluation of time extensions.

Therefore a majority of contractually specified methods, often called the time impact analysis, consists of the insertion of delay events into the most current schedule update that existed at the time of the occurrence of the event: a prospective method.

At the end of the project the choices of analysis methods are expanded with the full advantage of hindsight offered by the various forms of as-built documentation. In addition, if as-built documentation is available the best evidence rule demands that all factual investigation use the as-built as the primary source of analysis.

Also the timing distinction is often mirrored by a change in personnel. That is, often the forensic schedule analyst who typically works in the retrospective context is not the same person as the project scheduler who worked under the prospective context.

Layer 2: Basic Methods

The second hierarchy layer is the basic method, consisting of two branches, observational and modelled. The distinction drawn here is whether the analyst's expertise is utilized for the purpose of interpretation and evaluation of the existing scheduling data only, or for constructing simulations and the subsequent interpretation and evaluation of the different scenarios created by the simulations.

The distinction between the two basic methods becomes less defined in cases where the identity of the forensic analyst and the project scheduler rest in the same person.

1. Observational

The observational method consists of analyzing the schedule by examining a schedule, by itself or in comparison with another, without the analyst making any changes to the schedule to simulate a certain scenario.

Contemporaneous period analysis and as-built vs. as-planned are common examples that fall under the observational basic method.

2. Modelled

Unlike the observational method, the modelled method calls for intervention by the analyst beyond mere observation. In preparing a modelled analysis the analyst inserts or extracts activities representing delay events from a CPM network and compares the calculated results of the ‘before' and ‘after' states.

Common examples of the modelled method are the collapsed as-built, time impact analysis and the impacted as-planned.

Layer 3: Specific Methods

1. Observational Methods

Under the observational method, further distinction is drawn on whether the evaluation considers just the original schedule logic or the additional sets of progressive schedule logic that were developed during the execution of the project, often called the dynamic logic.

a. Static Logic Observation

A specific subset of the observational method, the static logic variation compares a plan consisting of one set of network logic to the as-built state of the same network. The term, ‘static' refers to the fact that observation consists of the comparison of an as-built schedule to just one set of as-planned network logic.

The as-planned vs. as-built is an example of this specific method.

b. Dynamic Logic Observation

In contrast with the static logic variation, the dynamic logic variation typically involves the use of schedule updates whose network logic may differ to varying degrees from the baseline and from each other. This variation considers the changes in logic that were incorporated during the project.

The contemporaneous period analysis is an example of this specific method. Note that this category does not occur under the prospective timing because the use of past updates indicates that the analysis is performed using retrospective timing.

2. Modelled Methods

The two distinctions under the modelled method are whether the delays are added to a base schedule or subtracted from a simulated as-built.

a. Additive Modelling

The additive modelling method consists of comparing a schedule with another schedule that the analyst has created by adding schedule elements (i.e. delays) to the first schedule for the purpose of modelling a certain scenario.

You will find under this variation, the impacted as-planned, and some forms of the window analysis method. The time impact analysis can also be classified as an additive modelling

method. But be aware that this term or its equivalent, time impact evaluation (TIE) has been used in contracts and specifications to refer to other basic and specific methods as well.

b. Subtractive Modelling

The subtractive modelling method consists of comparing a CPM schedule with another schedule that the analyst has created by subtracting schedule elements (i.e. delays) from the first schedule for the purpose of modelling a certain scenario.

The collapsed as-built is one example that is classified under the subtractive modelling method.

D. Layer 4: Basic Implementation

The fourth layer consists of the differences in implementing the methods outline above. The static logic method can be implemented in a gross mode or periodic mode. The progressive logic method can be implemented as contemporaneous: as-is, contemporaneous: split, modified, or recreated.

The additive or subtractive modelling method can be implemented as a single base with simulation or a multiple base with simulation.

1. Gross Mode or Periodic Mode

The first of the two basic implementations of the static logic variation of the observational method is the gross mode. Implementation of the gross mode considers the entire project duration as one whole analysis period without any segmentation.

The alternate to the gross mode is the periodic mode. Implementation of the periodic mode breaks the project duration into two or more segments for specific analysis focusing on each segment. Because this is an implementation of the static logic method, the segmented analysis periods are not associated with any changes in logic that may have occurred contemporaneously with these project periods.

2. Contemporaneous / As-Is or Contemporaneous / Split

This basic implementation pair occurs under the dynamic logic variation of the observation method. Both choices contemplate the use of the schedule updates that were prepared contemporaneously during the project. However the as-is implementation evaluates the differences between each successive update in its unaltered state, while the split implementation bifurcates each update into the pure progress and the non-progress revisions such as logic changes.

The purpose of the bifurcation is to isolate the schedule slippage (or recovery) caused solely by work progress based on existing logic during the update period from that caused by non-progress revisions newly inserted (but not necessarily implemented) in the schedule update.

3. Modified or Recreated

This pair, also occurring under the dynamic logic variation of the observational method, also involves the observation of updates. Unlike the contemporaneous pair, however, this implementation involves extensive modification of the contemporaneous updates, as in the modified implementation, or the recreation of entire updates where no contemporaneous updates exist, as in the recreated implementation.

4. Single Base, Simulation or Multi Base, Simulation

This basic implementation pair occurs under the additive and the subtractive modelling methods. The distinction is whether when the modelling (either additive or subtractive) is performed, the delay activities are added to or extracted from a single CPM network or multiple CPM networks.

For example, a modelled analysis that adds delays to a single baseline CPM schedule is a single base implementation of the additive method, whereas one where delays are extracted from several as-built simulations is a multi base simulation implementation of the subtractive method.

A single base additive modelling method is typically called the impacted as-planned. Similarly the single simulation subtractive method is called the collapsed as-built. The multi base, simulation variations are called window analysis.

Layer 5: Specific Implementation

1. Fixed Periods vs. Variable Periods / Grouped Periods

These specific implementations are the two possible choices for segmentation under all basic implementations except gross mode and the single base / simulation basic implementations.

They are not available under the gross mode because the absence of segmentation is the distinguishing feature of the basic gross mode. They are not available under the single base simulation basic implementation because segmentation assumes a change in network logic for each segment; the single base, simulation uses only one set of network logic for the model.

In the fixed period specific implementation, the periods are fixed in date and duration by the data dates used for the contemporaneous schedule updates, usually in regular periods such as monthly. Each update period is analyzed. The act of grouping the segments for summarization after each segment is analyzed is called blocking.

In the prospective timing mode, since there is usually only one forward looking set of network logic, be it the baseline or the current update, there is only one fixed period. Upon the creation of subsequent updates, by definition, the use of previous updates brings the analysis under the retrospective timing mode.

The variable period, grouped period specific implementation establishes analysis periods other than the update periods established during the project by the submission of regular schedule updates.

The grouped period implementation groups together the pre-established update periods while the variable windows implementation establishes new periods whose lines of demarcation may not coincide with the data dates used in the pre-established periods and/or which can be determined by changes in the critical path or by the issuance of revised or recovery baseline schedules.

This implementation is one of the primary distinguishing features of the window analysis method.

2. Global (Insertion or Extraction) vs. Stepped (Insertion or Extraction)

This specific implementation pair occurs under the single base, simulation basic implementation, which in turn occurs under the additive modelling and the subtractive modelling specific methods. Under the global implementation delays are either inserted or extracted all at once, while under the stepped implementation the insertion or the extraction is performed sequentially (individually or grouped).

Although there are further variations in the sequence of stepping the insertions or extractions, usually the insertion sequence is from the start of the project towards the end, whereas stepped extraction starts at the end and proceeds towards the start of the project.